Closed-Loop Manufacturing

Benefits of Sustainability

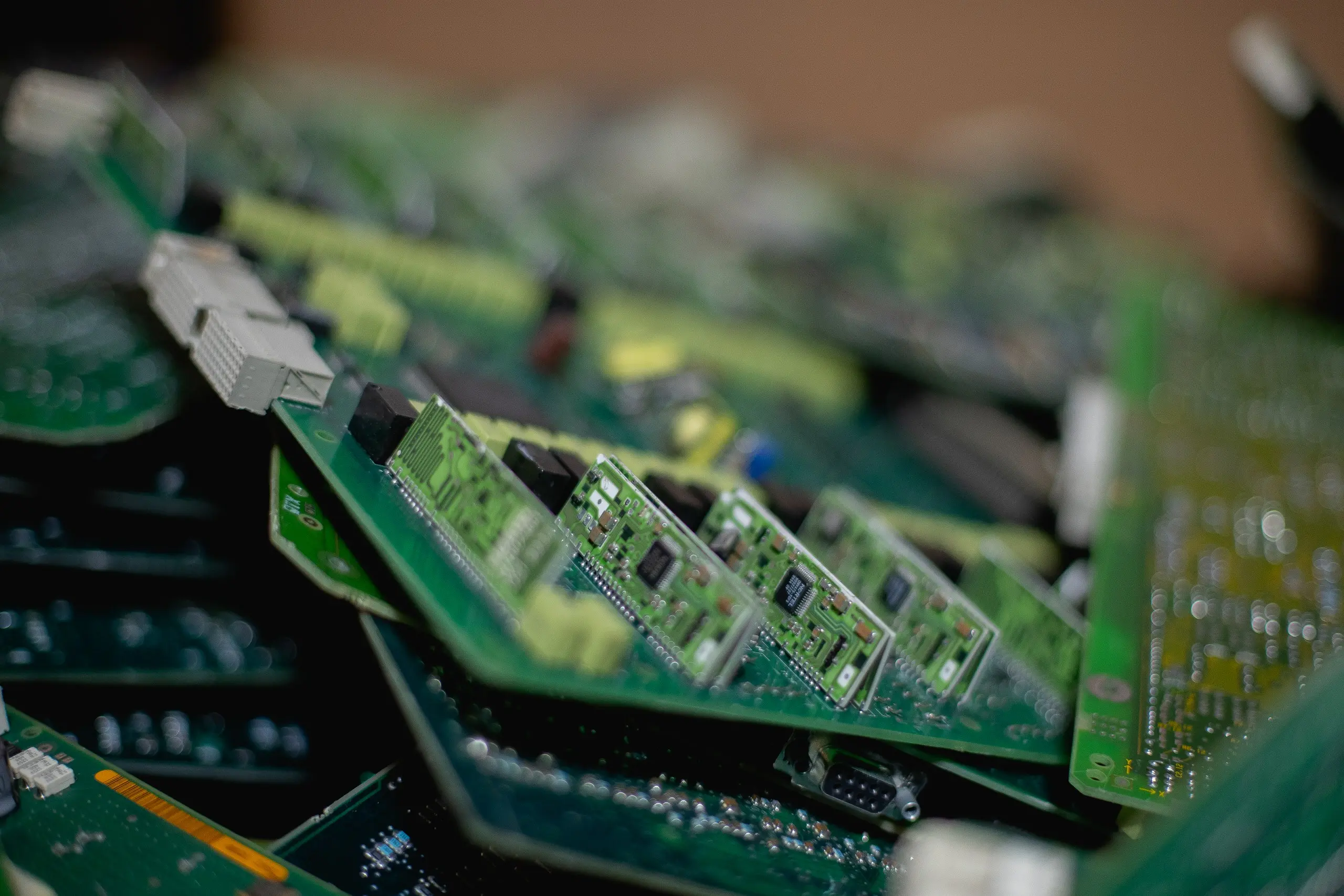

Closed-loop manufacturing is about reusing materials to create new products. At Genesis Dome, we recognize the importance of this model. Our closed-loop manufacturing solutions promote innovation and optimization in the manufacturing sector.

✔ Optimized Supply Chains — Supply chain optimization is possible by adopting a closed-loop manufacturing system. Optimization for individual enterprises involves re-using and re-purposing materials whenever possible. This approach enables manufacturers to use resources efficiently.

✔ Fewer Resources — Closed-loop manufacturing lowers expenses by reducing the need for raw materials. Conserving resources creates additional value and helps manufacturers become more efficient.

✔ Design Innovation — Closed-loop manufacturing cultivates design innovation as it seeks to find more environmentally friendly, efficient, and cheaper solutions to produce new products. Upcycling is another benefit of this process because it often creates higher-quality products.

✔ Brand Protection — Closed-loop manufacturing keeps recyclable co-products out of landfills and avoids brand-damaging press. Closed-loop systems also make it difficult for competitors to integrate aspects of your product. Your brand becomes more protected as a result of pursuing closed-loop manufacturing.

✔ Conservation — Closed-loop manufacturing reduces carbon footprints because many materials can be used repeatedly during the manufacturing process. This type of manufacturing is an environmentally friendly solution for manufacturers because it reduces waste output and conserves natural resources.

✔ Optimized Supply Chains — Supply chain optimization is possible by adopting a closed-loop manufacturing system. Optimization for individual enterprises involves re-using and re-purposing materials whenever possible. This approach enables manufacturers to use resources efficiently.

✔ Fewer Resources — Closed-loop manufacturing lowers expenses by reducing the need for raw materials. Conserving resources creates additional value and helps manufacturers become more efficient.

✔ Design Innovation — Closed-loop manufacturing cultivates design innovation as it seeks to find more environmentally friendly, efficient, and cheaper solutions to produce new products. Upcycling is another benefit of this process because it often creates higher-quality products.

✔ Brand Protection — Closed-loop manufacturing keeps recyclable co-products out of landfills and avoids brand-damaging press. Closed-loop systems also make it difficult for competitors to integrate aspects of your product. Your brand becomes more protected as a result of pursuing closed-loop manufacturing.

✔ Conservation — Closed-loop manufacturing reduces carbon footprints because many materials can be used repeatedly during the manufacturing process. This type of manufacturing is an environmentally friendly solution for manufacturers because it reduces waste output and conserves natural resources.

Contact Our Team

From secure electronics disposal to tailored industry solutions, we’re here to help.

Connect with our team today for reliable, eco-friendly waste management services.